Open Pocket Washer/ Extractors

Jump To:

Choose a Section

Jump To:

OPEN POCKET WASHER/EXTRACTORS

Available in processing capacities of 250-300, 400-600 and 600-700 lbs., dry weight load sizes. All Braun Open Pockets can be ordered for chute loading.

SEE MORE

Special Features

Loading Options – Chute Load Open Pocket Washer/Extractors

Chute Load Open Pocket Washer/Extractors

- Braun open pocket washer/extractors can be ordered for chute loading for fully automated wash rooms.

- This loading option removes the potential for serious injury to the operator from pushing bags into a moving washer cylinder.

Ride-On Shuttle System Loading Option

- Braun fully automated open pocket washer/extractor systems can be loaded by the Braun Ride-On SafeLoad® Shuttle System.

- This loading option removes the potential for serious injury to the operator from pushing bags into a moving washer cylinder.

Air Loading Option

- Braun open pocket washer/extractors can be ordered for chute loading for fully automated wash rooms.

- Shown in this picture is an air loading option

Large Door Opening

- 250 lb. Open Pocket features a 40” diameter standard large door opening allowing for 200 to 300 pound operating capacity depending on the goods

- 450 lb. Open Pocket features a 40” diameter standard large door opening allowing for 400 to 600 pound capacity depending on the goods classification.

- 675 lb. Open Pocket features a 48” diameter standard large door opening allowing for 600 to 700 pound capacity depending on the goods classification.

- Braun open pocket machines commonly run walk off mats at weights above the noted capacity.

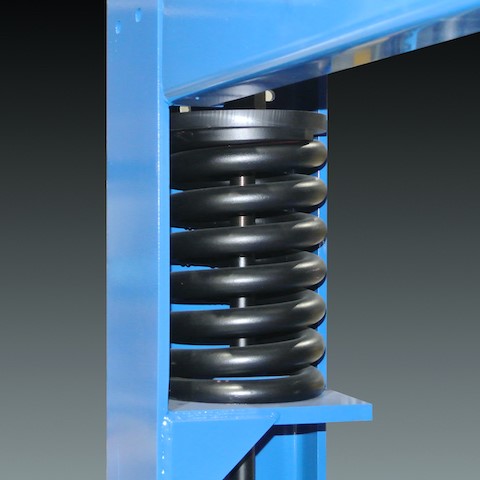

Neutron Suspension

Braun’s Neutron Suspension:

- Unsurpassed vibration dampening allows for installation even on upper floors that can hold the static

- Isolates vibration from the workspace

- Promotes less wear on major end components for exceptional durability and machine longevity

- Provides for consistent wash performance

- Neutron system is very simple vs. an air bag system

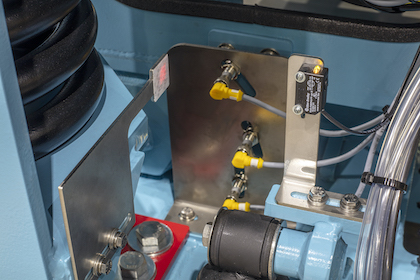

- Air bag systems require a variety of valves and synchronization the of air bags. Timing is critical for smooth operation.

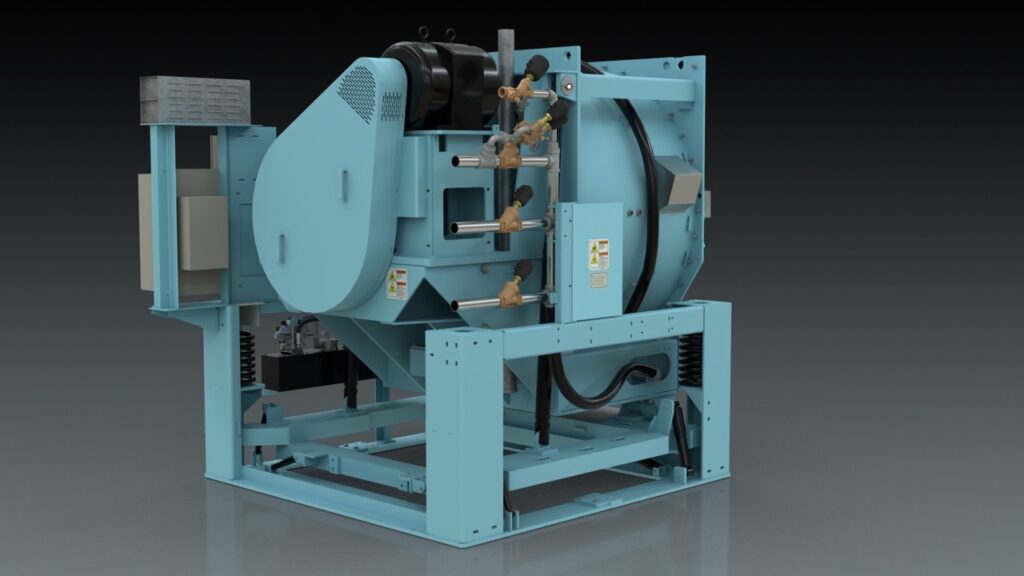

Single Motor Drive

Energy efficient drive technology:

- Ramps up to full speed smoothly without stepping, without fixed speeds, to programmable extraction speeds up to 625 rpm.

- Allows the machine to pin goods and then go into higher Extract speeds removing more water quickly before Sending the goods on to the dryer, ironer or tunnel finisher. More thoroughly extracted goods result in shorter dryer times and lower natural gas costs!

- Using fewer and less complicated parts, single motor drive open pockets promise less down time and dollars spent on maintenance…..therefore a reduced cost of ownership.

- A rinse reuse option is available to install Braun open pockets to a split trench system allowing for optimal water conservation.

Chemical Integration

- Chemical integration boxes are standard on all Braun Open Pocket Washer/Extractors.

- This feature provides an input and output module for chemical companies to tie into Braun machines without having to access the control box. This helps to avoid interference with the machine controls and any related machine downtime as a result of any potential interference.

Auto Load Rebalance Technology

Optical sensors on Braun open pockets will instruct the machines to:

- Automatically shut down if they are overloaded

- Automatically balance loads prior to moving into the extraction phase to evenly distribute wet goods against the cylinder, eliminating the need for artificial counterbalances

- Tamper Proof Solution

- Plug and Play

Touch Screen Controls

Simple, intuitive, and easy to use touch screen controls

- Conveniently located USB flash drive to simplify program loading and backup

- 24 Volt Control Panel

- Interchangeable Flash Card/Configurable to Machine

- Operators can pre-program and time every cycle and water temperature and level to an exacting degree.

- Used on all Braun Machines

Water Reclamation System (Open Pocket Washer Option)

- Reclamation tank recovers 173 gallons of water (450 lb. OP) and 225 gallons of water (650 lb. OP)

- Water typically comes from the final rinse of the previous load, which is then added to the initial fill cycle of the next load

- Minimal Footprint – only 4.5″ deeper than the existing yellow fence/guarding (450 OP), and only 6.25″ deeper on the 650 OP!

- Can be retrofitted on any touchscreen-controlled open pocket washer

- Quick disconnect fittings (hose and electrical cables), and caster wheels for easy access to the washer

- Environmentally friendly

- Contact us to develop a compelling ROI for your laundry facility!

Jib Crane

- Optional Open Pocket Washer Maintenance Tool

- Capable of removing motors, sheaves, bearings, etc.

- Load rate up to 1,000 lbs.

- Available for 400 – 650 lb. Open Pocket Washers

Product Videos

Tilt

Facts

Product Literature