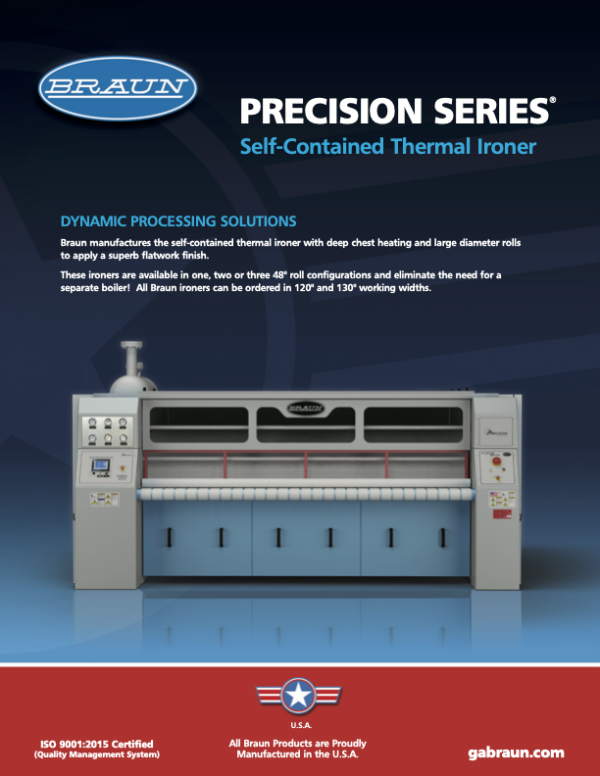

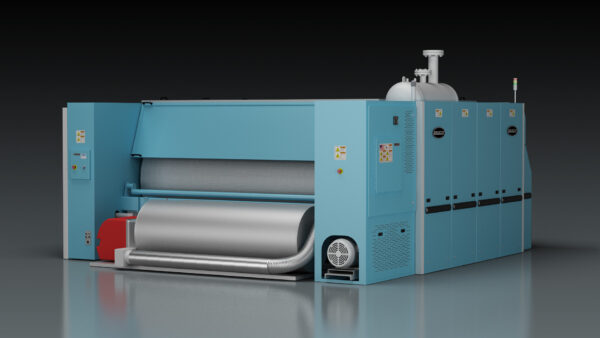

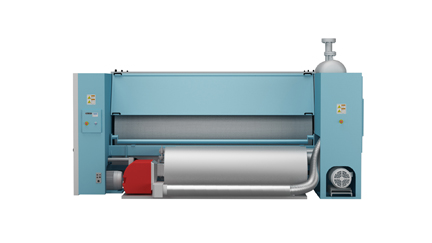

Precision Series® Self-Contained Thermal Ironers

Jump To:

Choose a Section

Jump To:

Precision Series® Self-Contained Thermal Ironers

Braun Self-Contained Thermal Ironers are available in one or two 48” roll configurations in 120” or 130” working

widths. These machines eliminate the need for a separate boiler.

SEE MORE

Special Features

Introduction

Self-Contained

Thermal Ironer

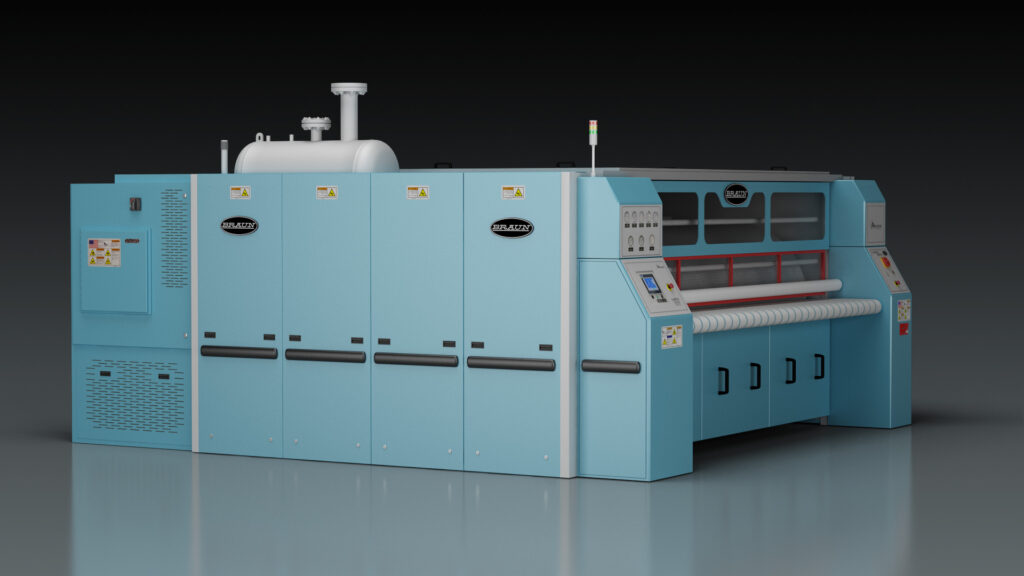

- Available in one, two or three 48″ roll configurations and 120″ or 130″ working widths

- Ideal for laundries that need a new ironer, do not want to change their existing boiler or add a new boiler and are looking for an energy efficient option!

- Braun self-contained thermal ironers are manufactured with deep chest heating and large diameter rolls to apply a superb flatwork finish.

- Factory Support – The benefits of the Braun Self-Contained Thermal Ironer extend beyond the machine. Our clients enjoy easy access to replacement parts, a team of regionally located, factory-trained Braun field service technicians, and Free 24/7 telephone technical support for the life of the equipment!

Tank Design

Efficient Heating – Safe Operations

- Features a three chamber expansion tank design

- Tank design incorporates a thermal buffer and deaerator and does not require a nitrogen gas blanket. This provides for extended longevity and life of the oil.

- Heat exchanger has a nested concentric helical wound coil using a 3-pass design – which is the most efficient in today’s market.

- Modulating burner control system with a 5:1 turndown provides precise heater control

- Unique tank design is ideal for laundries with limited space and protects fluid from oxidation.

- Expansion tank shield is a man-safe device, which is easy to remove for tank access and rountine maintenance

- Braun recommends only Paratherm NF thermal oil due to its low coefficient of expansion and because it is environmentally friendly.

Ironer Energy Efficiency

Don’t Be Misled!

Using the simple relationship of oil temperature to chest temperature, all thermal ironers exceed a 90% efficiency rating.

This is not an overall systems energy consumption efficiency measure. This is only the ability of the hot oil to release its heat energy to the sheet. This is true of thermal fluid in general and qualifies known industry advantages of thermal oil over steam ironers. Don’t be misled – this measurement of heat transfer is not a measure of system efficiencies.

Pipes, Flanges, Valves, and Insulation

- Exceptional fit, finish, and appearance!

- Abrasion resistant

- Will not melt or degrade under ironer operating conditions

- Will bring surface temperature to man safe levels

- Insulation jackets are cost effective and easy to remove for maintenance and rigging.

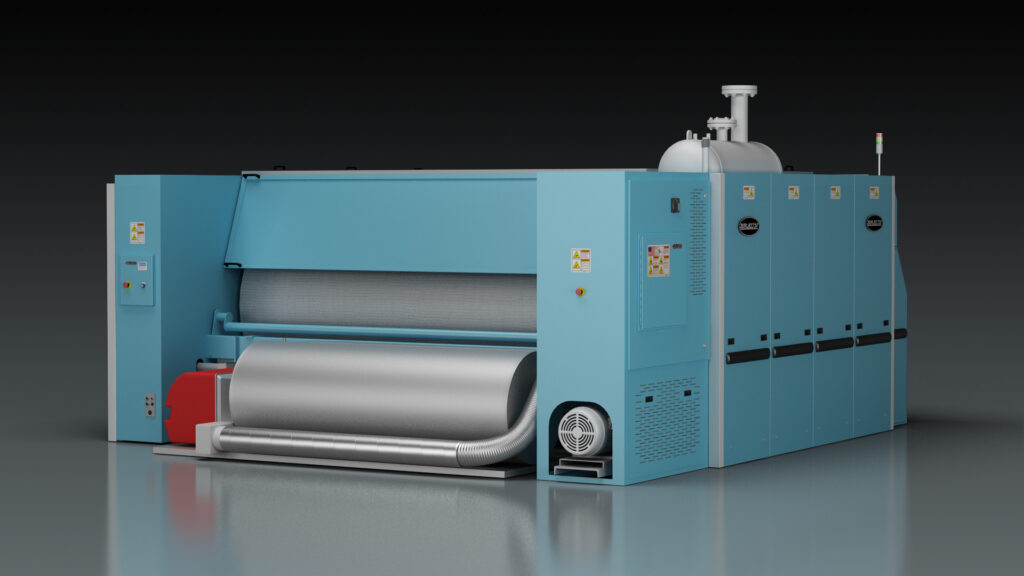

Ironer Rolls Lift Out of Chest

- Ironer rolls can be lifted up to 14” out of the chest by pneumatic pressure cylinders, allowing easy cleaning and padding. If air pressure or power is suddenly lost, all rolls lock into position to prevent accidental lowering.

Side Frames Design

- Side frames were designed to disclose interior supports

- Inner guards were made removable for access into ironing cavity

- This design increases maintenance access and serviceability

- All maintenance activities are done through the side frame

Multi-Motor Drive

- The multi-motor drive utilizes a single gearmotor per roll section, eliminating the need for costly sprockets, belting, and bearings

- Ergonomic design reduces set-up time and maintenance requirements

- Plug and play connections allow for fast and easy installation and replacement

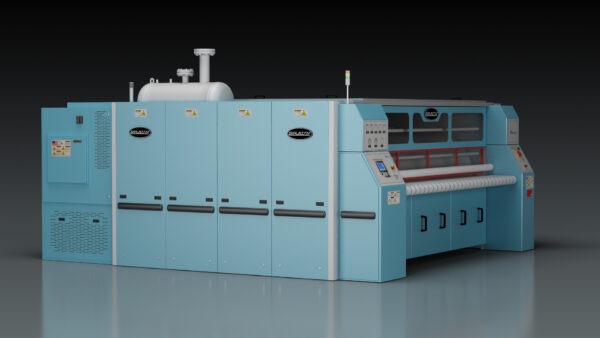

Tape Guides

- Tape guides on Braun ironers are conveniently located at the front of the ironer making them easily accessible. Others on the market are located at the back of the ironer and require a catwalk to access them. Not only are they difficult to access, the catwalk could compromise operator safety and adds to the ironer’s footprint, taking up additional real estate.

Tension Wheel

- The tension wheel is used to prevent the ironer ribbons from constantly running in the same spot on the pads. If left to do so, the ribbons would eventually wear out sections of the ironer pad, creating uneven surfaces which will translate to lines and wet spots on sheets.

Multi Inverter Drive System

- Multi Variable Frequency Drive (VFD) control system allows for the precise control of each roll section.

- Individual roll speeds can be varied to allow for smooth transition of linens through the ironer without stalling or bunching.

Controls

- 24 V Color Touch Screen Controls System

- Simple, intuitive, and easy to use

- Program backup to USB drive

- English & Spanish are standard (other languages are optional)

- Ethernet capability

- 99 Programmable formulas for different goods

- Alarm history accessibility

- Ability to check individually activate Inputs and Outputs

Safety Features

- Finger guard protection prevents accidental contact with heated surface and rolls

- Rolls are automatically raised in the event of a power interruption to avoid scorching of flatwork and ironer padding.

- The ironer starts with roll pressure relieved, reducing starting torque and ampere inrush.

- Standard canopy prevents foreign objects from falling between rolls

Vacuum Assist

- An ironer vacuum assist table is an available option.

Options

Voltage

- 380 volt – 3 phase – 60 cycle (Transformer)

- 600 volt – 3 phase – 60 cycle (Transformer)

- 380 volt – 3 phase – 50 cycle (Transformer)

- Propane gas fired thermal fluid heater

- Vacuum assist feeding option with 120″ or 130″ working width

- Polycarbonate clear side access panels

- Color other than Braun blue

Product Videos

Deep Chest Ironing Process

Deep Chest Ironing Process (Spanish)

Thermal Fluid Delivery & Safety Features

Self Contained Thermal Ironer

Product Literature