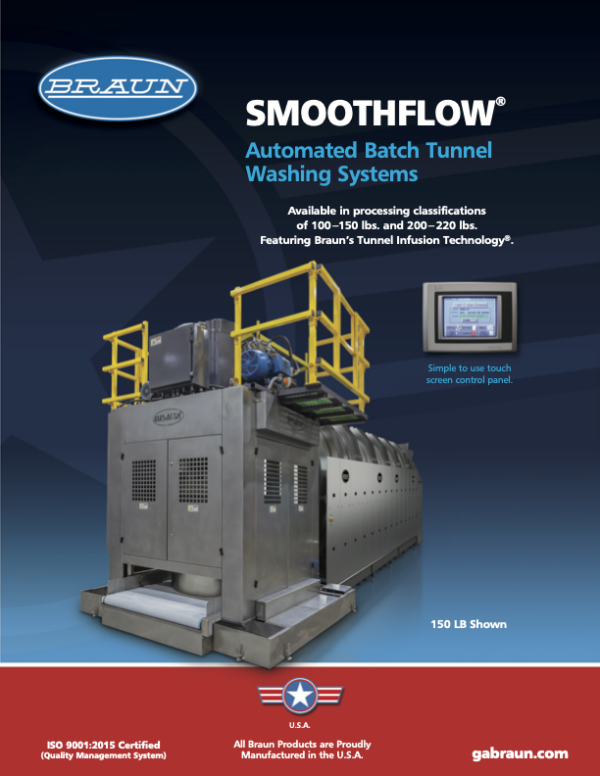

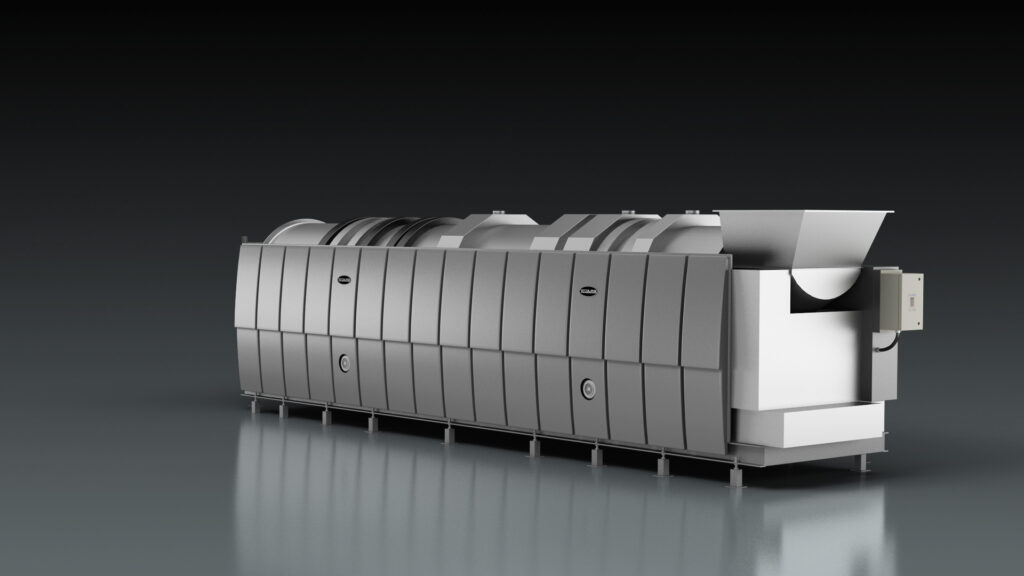

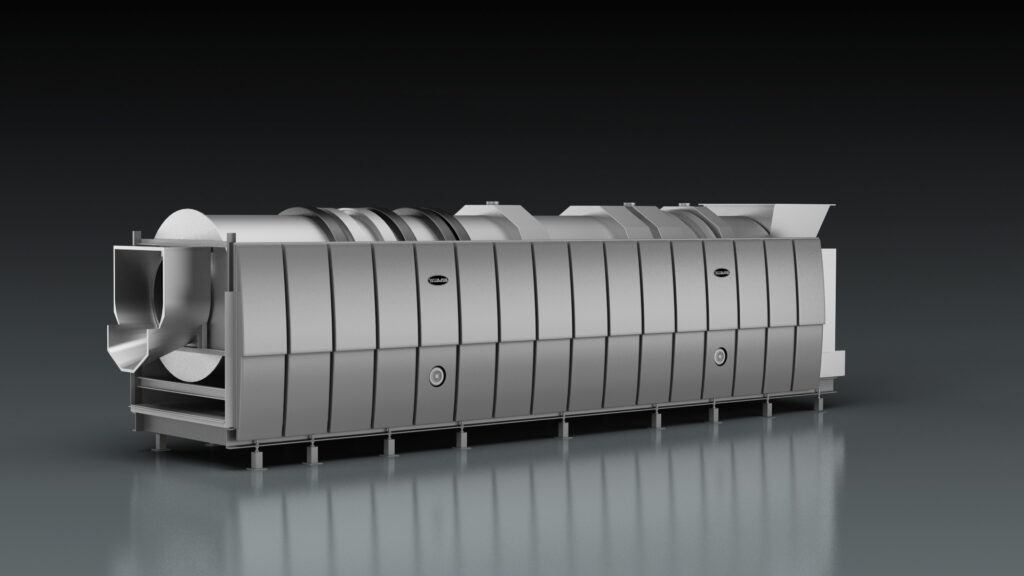

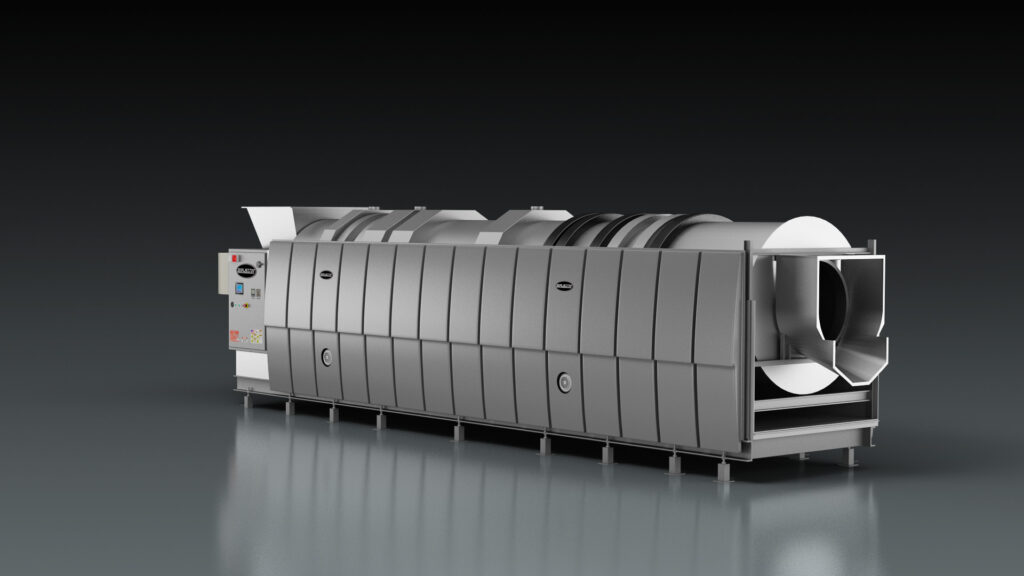

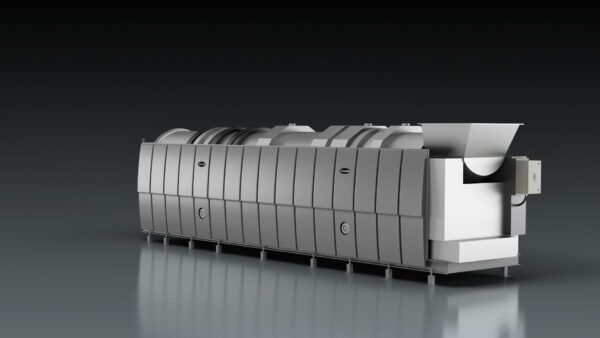

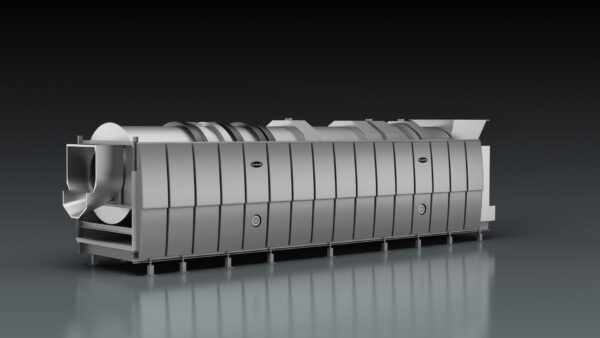

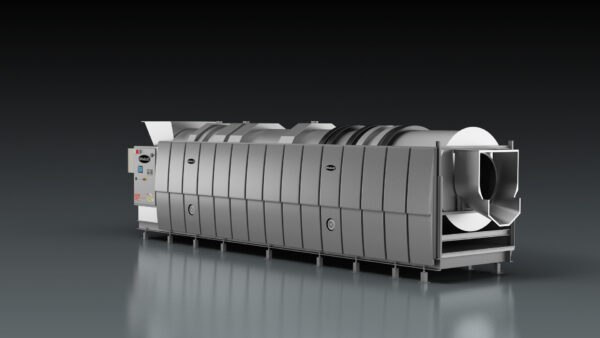

SmoothFlow® Batch Tunnel Washer 130 lb. Model

Jump To:

Choose a Section

Jump To:

SmoothFlow® Batch Tunnel Washer 130 lb. Model

SEE MORE

Special Features

Proven Technology

Proven Technology

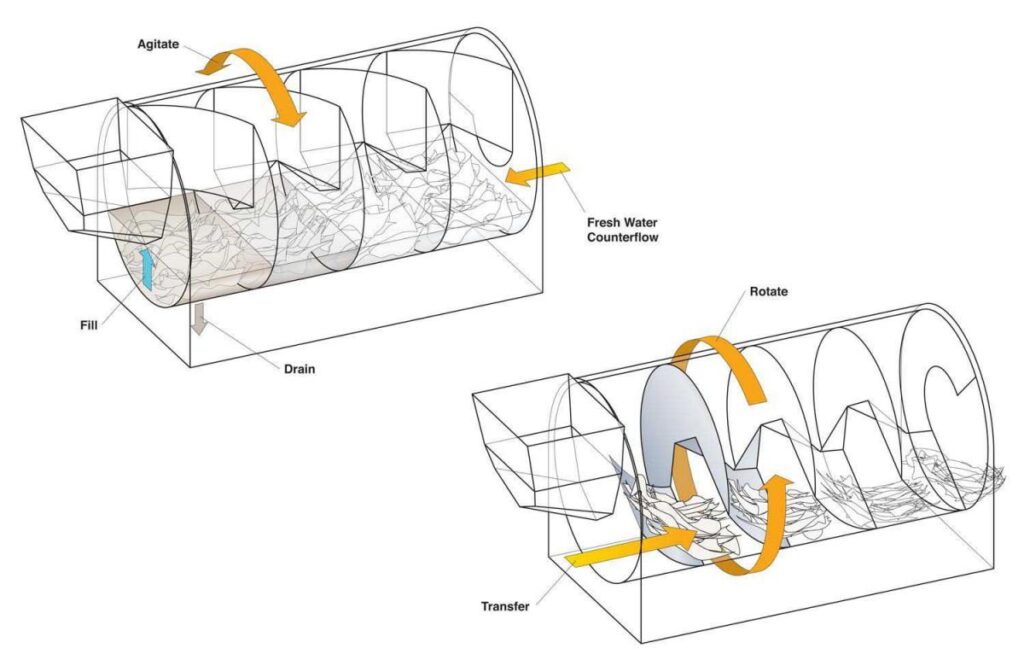

- Braun’s Tunnel Infusion Technology is utilized throughout the tunnel. This is Braun’s trademarked fill process of adding water and chemistry above the goods for superior agitation and mixing.

- Positive Transfer process allows for maximum utilization of the machine’s processing capacity.

- Braun tunnels operate with the mechanics of an open helicoid process unlike tunnels using a true archimedial screw.

- Unparalleled mechanical action – each chamber washes with a similar level of mechanical action as an open pocket washer for exceptional wash quality.

- Reverse rotation capability! In the event of a double batch error, Braun tunnels have the ability to reverse rotate manually if needed, eliminating the need to enter the tunnel to clear the goods.

- Counterflow is accomplished through compartment walls, which eliminates inside seals that are difficult to monitor and service.

- Between zones, solid compartment walls keep all wash solutions separated. In the normal standby and transfer positions, total separation exists between batches and 100% batch integrity is assured.

Key Features

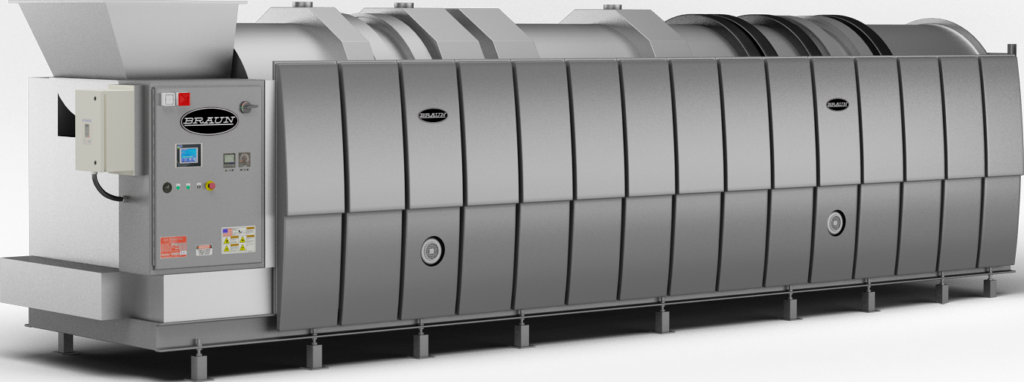

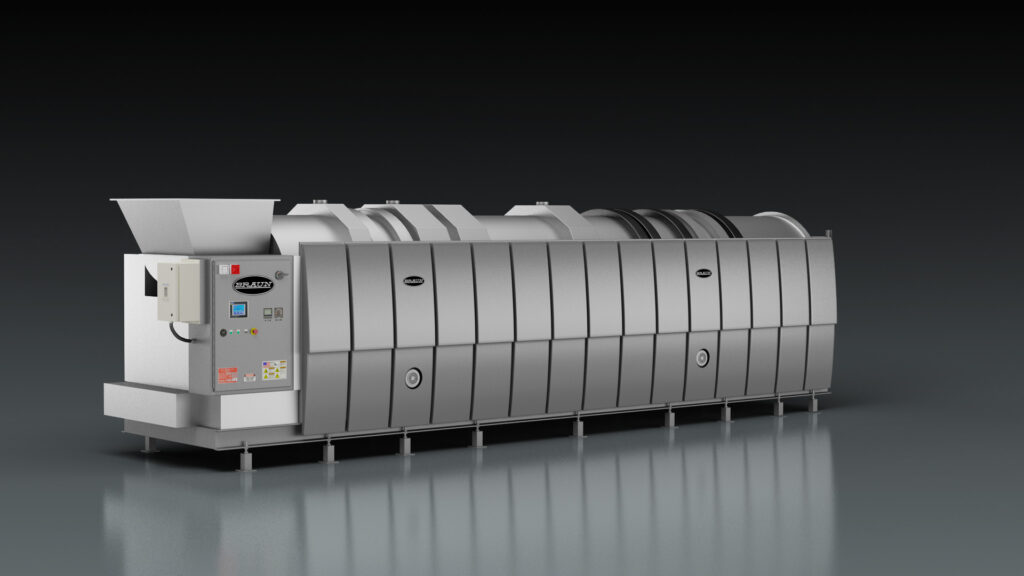

- Single-drum design eliminates cumbersome maintenance as with double-drum systems

- Single-drum and positive transfer process allows for maximum utilization of the machine’s processing capacity.

- Mono-shell design utilizing stainless steel provides perpetual cleaning of the cylinder affording a processing environment for the effective and hygienic processing of linens.

- Contoured and welded inner walls for strength and positive transfer

- Easy-to-replace rubber seals allow water in, chemical injection and water out

- Flexible and simple to use controls

- Allows for an efficient processing environment

- Can be mounted on curb or jack stands

- Can be loaded with pocket loader or by rail

- Dependable and proven track record

- Allows for an efficient processing environment

- Can be mounted on curb or jack stands

- Can be loaded with pocket loader or by rail

- Dependable and proven track record

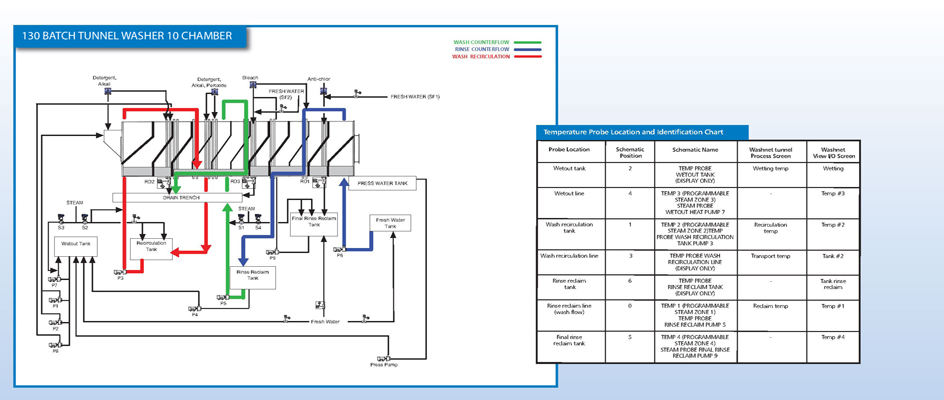

Process Flow Diagram (10 Chamber)

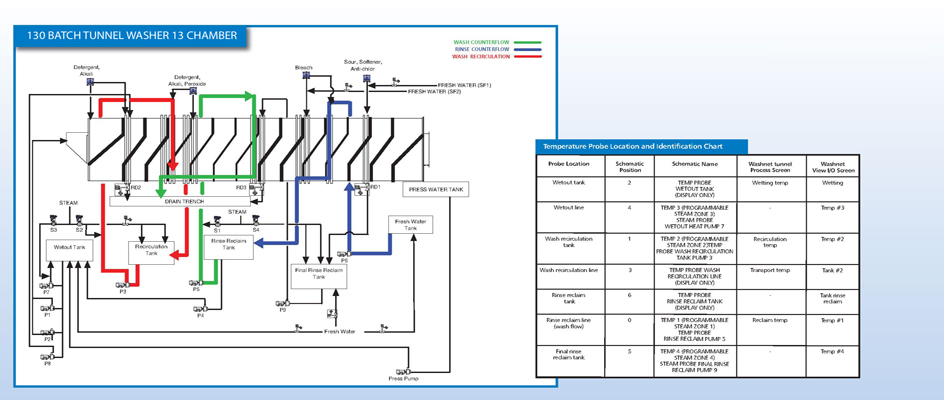

Process Flow Diagram (13 Chamber)

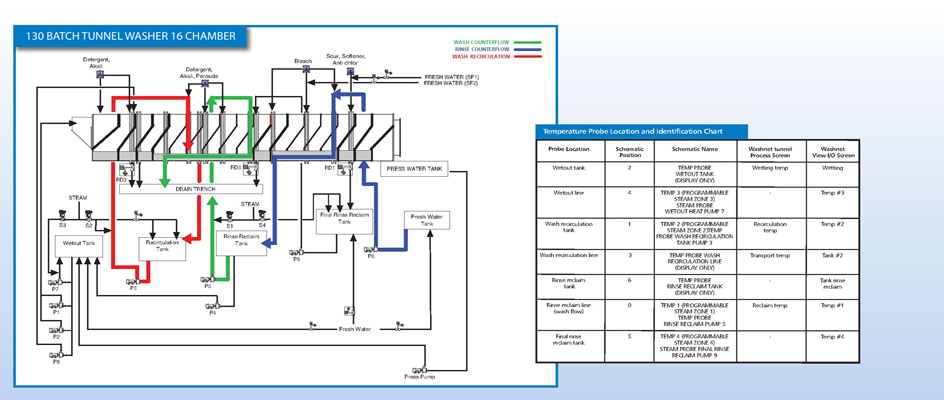

Process Flow Diagram (16 Chamber)

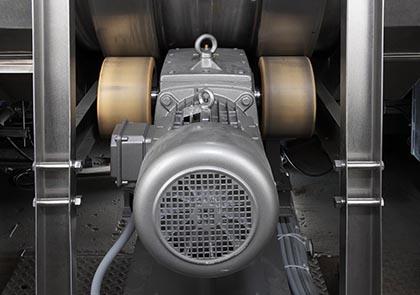

Drive System

- The drive system is simple, rugged and reliable.

- Friction drive eliminates chains and belts that can stretch and break, and no sprockets that wear.

- Easy to replace motor can be changed without having to change the gear box

- Four motors – will run on three if one should fail

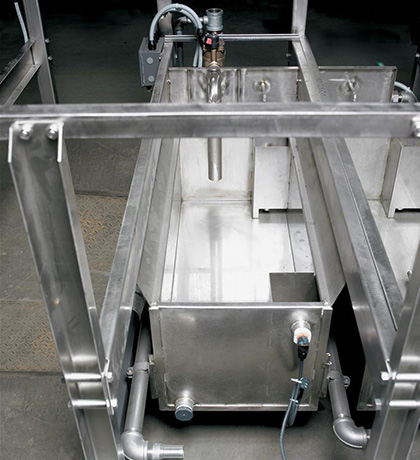

Fresh Water Reservoir

- The fresh water reservoir guarantees continual fresh water regardless of fluctuating water pressure in the plant.

- Water recovery and reuse systems ensure all possible process water is captured and recycled throughout the entire machine

- Hydraulic cooling water from the press…..press water is re-used as either rinse, make up water to the wash, or in the pre-wash of the machine

- Recovery of water from seal wetting and unintended overflow to the rinse reclaim tanks

- Every stream in the Braun tunnel is reused at least once

- Water usage on Braun tunnels range from 0.5 – 0.8 gallons per pound of linen depending on the goods soil classification and wash process.

Chemical and Water Injection Area

Water and chemistry are injected at this location with the chemistry added above the water level for proper and thorough mixing.

Heating Source

Unique to the Braun tunnel, the external heating source eliminates direct contact of steam to the goods. This assures the quality of the process.

Touch Screen Controls

- Simple, intuitive, and easy to use

- Braun controls aid in formula management and allow for valuable operating data to be available at the touch of a finger.

- Conveniently located usb flash drive to simplify program loading and backup

- 24 Volt Arc Flash Safe Control Panel

- Interchangeable Flash Card/Configurable to Machine

- Operators can pre-program and time every cycle and water temperature and level to an exacting degree.

- Used on all Braun machines

Product Videos

Positive Transfer Process

130lb Tunnel Processing Flow

Batch Tunnel Washing and Infection Control

Product Literature