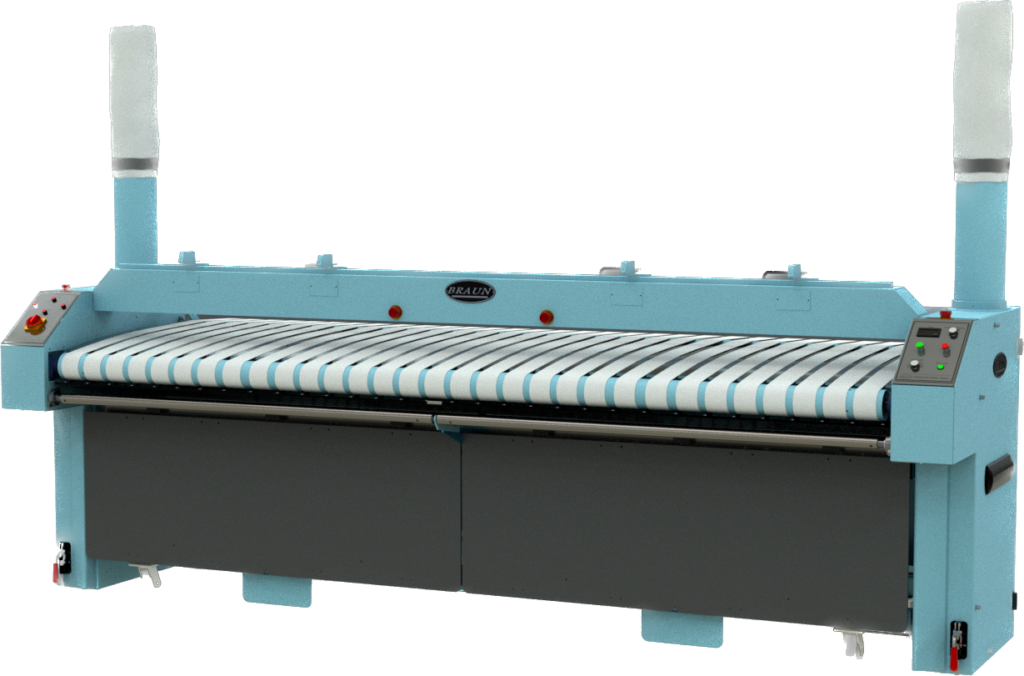

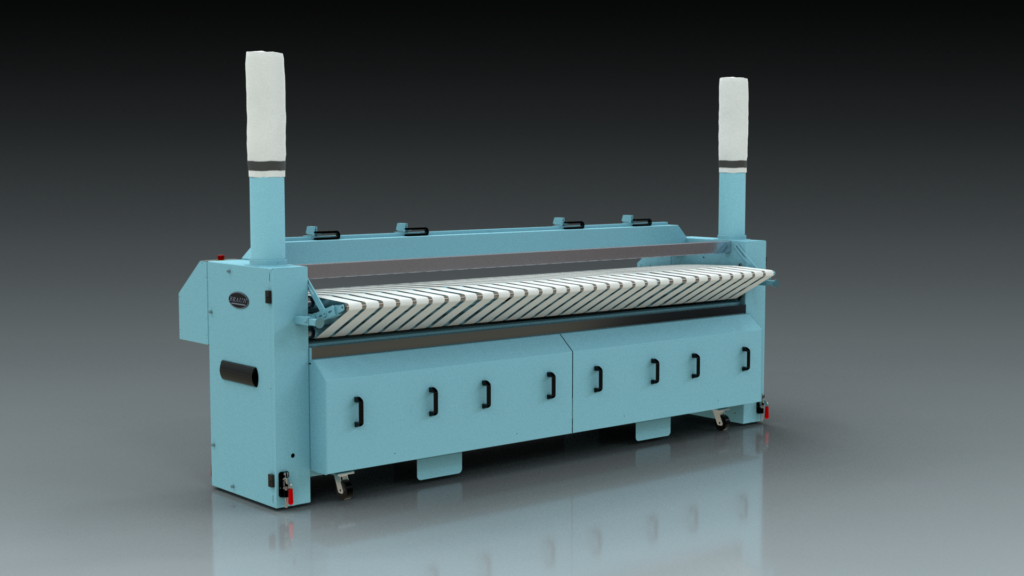

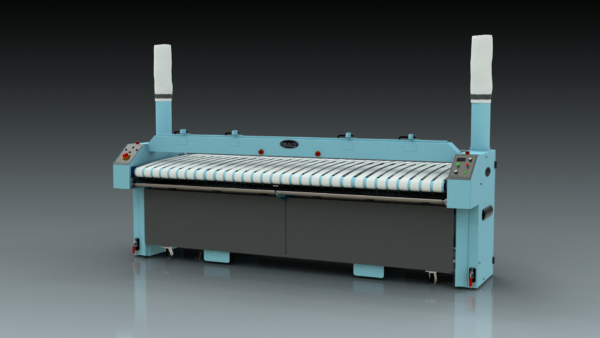

SpeedVac® Feed table

SpeedVac® Feed table

Special Features

Overview

Braun’s SpeedVac® accurately processes a wide range of goods – from small flawork pieces such as napkins, pillow cases and table linens, to California king sheets with dependable, repeatable quality.

The inverter-driven feed deck is easy to operate and offers variable range speed control to ensure the pieces are taut and aligned for a positive leading edge. The adjustable laser lane indicators provide visual piece positioning.

This feed table assists feeding on both the table top and the trailing edge without cumbersome pressure wheels. And with the vacuum flow equally distributed across the width of the table, different size goods may be processed wtih non-lane dependent feeding.

An adjustable discharge conveyor meets the requirements of different height ironers, and a built in work light allows for enhanced real-time quality control inspection. Easy-to-clean two-stage lint filters ensure minimal exhaust restriction.

The SpeedVac is also available with optional digital production counters for each of the feed lanes to easily monitor processing efficiency.

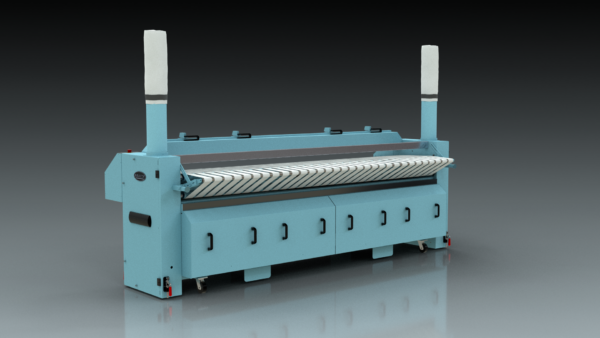

Standard Features

- Vacuum assist feeding of small and large pieces to an ironer

- Adjustable laser lane indicators to provide repeatable guides for hand feeding

- Simple lint collection bags mounted above each side panel

- Programmable inverter-type variable speed conveyor drive with digital speed indicator

- Fluorescent lit feed deck

- Caster-mounted for easy movement

- Illuminated Emergency Stop

- 130” working width

- Standard voltages: 208, 240, 480 volt, 3 phase, 60 cycle

- Variable speed blower control for easy adjustment of vacuum air flow

- Door alarm indicators

Note:

- Available with optional 120” working width for 4 or 5 lane processing

- Available with optional digital production counters for each of the feed lanes

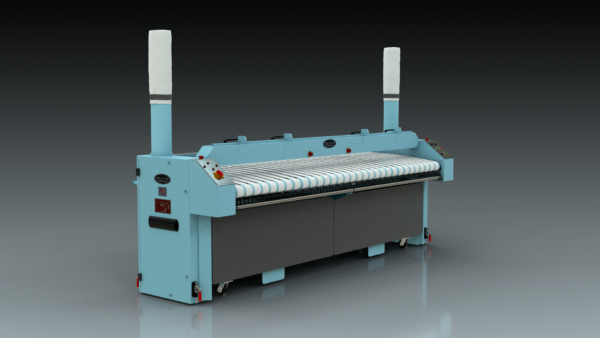

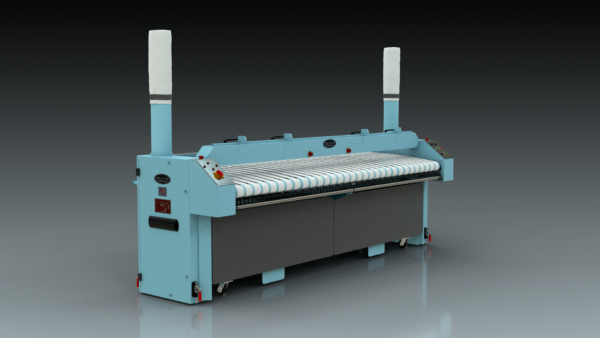

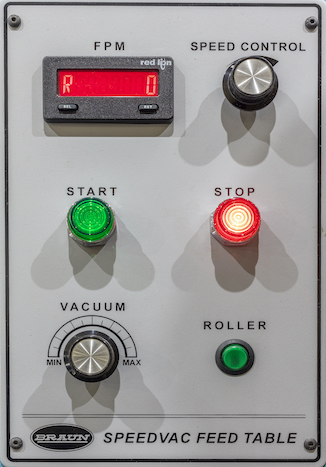

Speed Control

The inverter-driven feed deck is easy to operate and offers variable range speed control to ensure the pieces are taught and aligned for a positive leading edge.

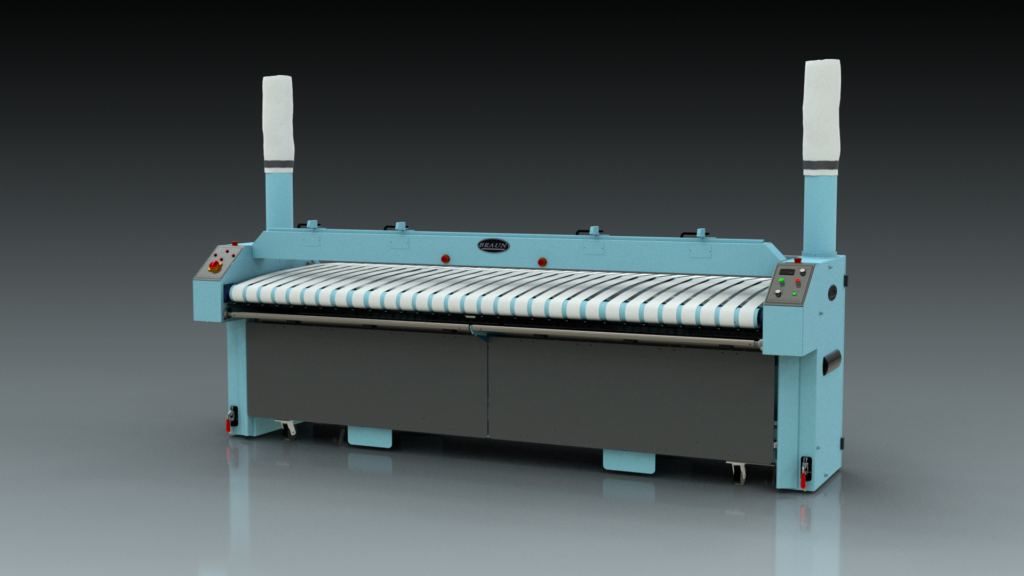

Power Panel

Easy to access and operate!

Laser Lane Indicators

- The adjustable laser lane indicators provide for visual piece positioning and aid in quality control.

- Fluorescent lighting helps to detect defects which also enhances quality control.

Adjustable Discharge Conveyor

- An adjustable discharge conveyor meets the requirements of different height and width ironers.

Blower Accessibility

Rear covers are easily removable should you need to access the blowers.

Lint Collection

Easy-to-clean lint collection bags and easy access to the cylinder’s lint collection unit add to the simplicity and efficiency of operation.

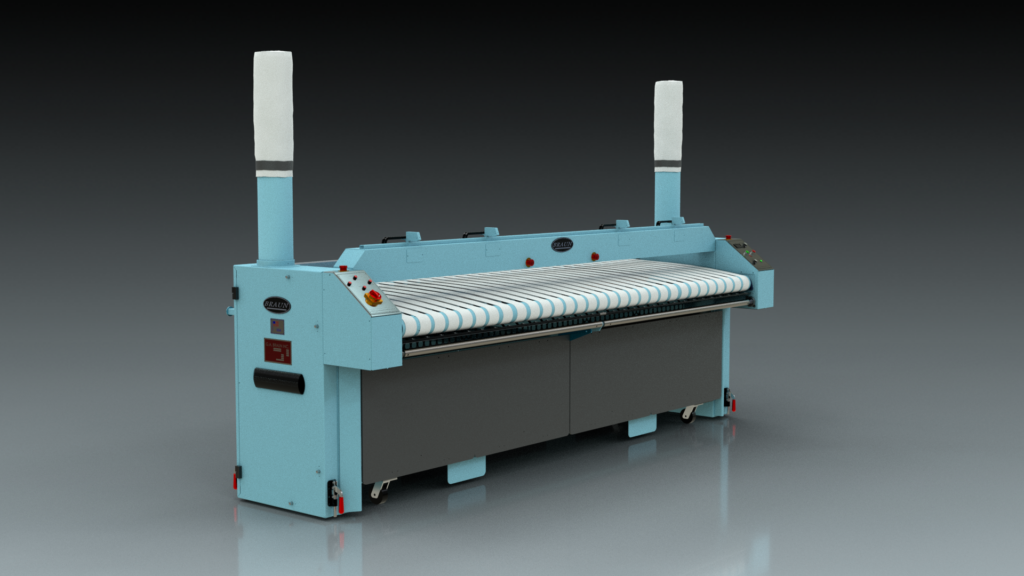

LED Lane Counters (Optional)

- Each lane can be individually counted to easily monitor processing efficiency

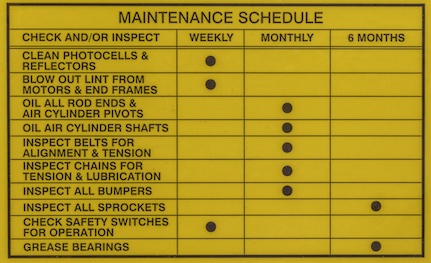

Routine Maintenance

The routine maintenance schedule is clearly posted on the machine to help operators improve the life of the equipment and to minimize unplanned maintenance activity.

Product Videos

SpeedVac

Product Literature