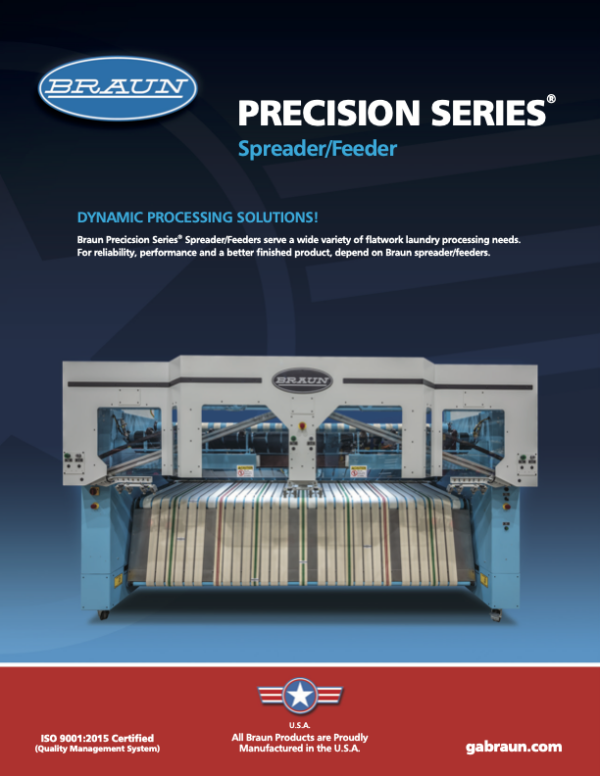

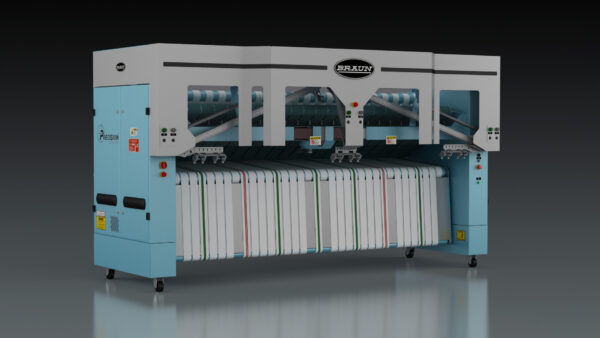

Spreader Feeders

Jump To:

Choose a Section

Jump To:

Spreader Feeders

SEE MORE

Special Features

Overview

Overview

- Serves a wide variety of flatwork laundry processing needs including hospitality, healthcare, commercial linen, and general industrial laundries

- Servo drive technology provides accurate and fast spread and laydown of large piece items

- Patent spread detection and speed synchronized spread belts

- Infeed laydown functionality provides consistent quality feeding

- Easily processes fitted sheets!

- Single point transfer and positive center point spreading – assures mininal drops and accurate centering – maximizies line productivity

- Lower feed carriage heights

- Ball bearing carriers for all transport motions

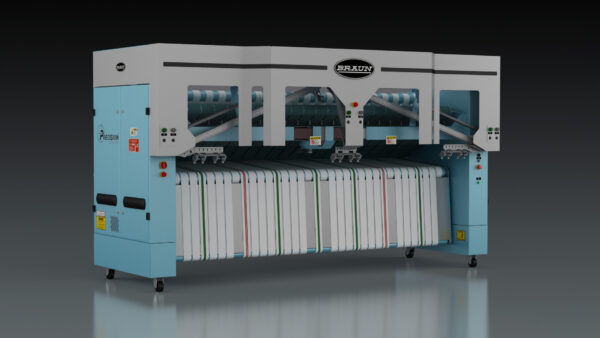

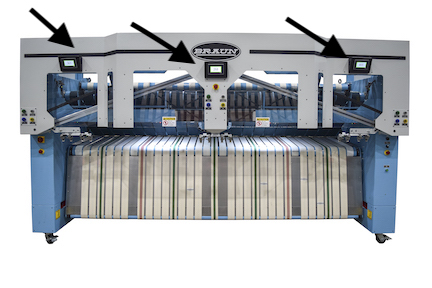

- Two or Three operator station options

- Production line speeds of 125 fpm (feet per minute)

- Manufactured with fewer moving parts than others on the market!

- Built to withstand the wear and tear of today’s high-volume laundry environments

- Automated spread clamp jam detection

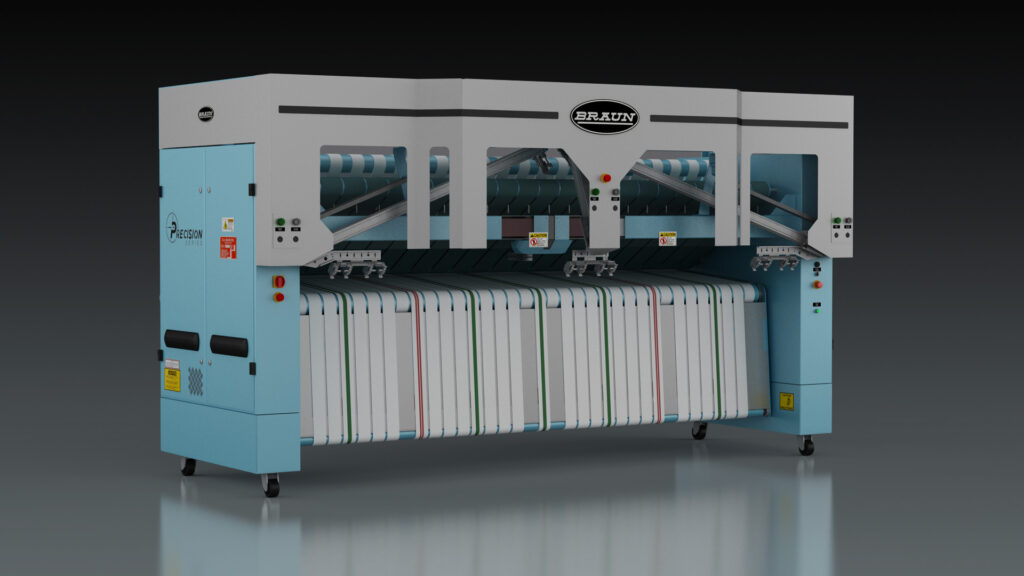

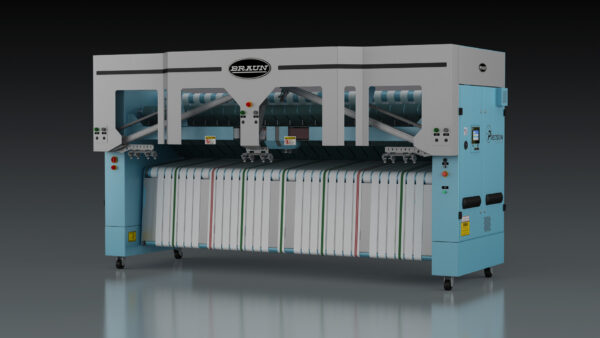

Exceptional Leading Edge and Trailing Edge

- The automatic leading edge and width transfer programming allows for a seamless transition for those plants that process mixed items in a single lane. This stress relief capability assures a smooth transfer from the spread mechanism to the feed table and provides for an extraordinary high quality leading edge.

- This process as opposed to others on the market does not require using a host of air knives or jets to try and clean up the leading edge post spreading. Additionally, other models have more sheet losses as they use more air which increases the margin of error. Braun machines take one transfer from the operator to the machine. This is done through a mechanical process that assures consistent part centering each and every feed.

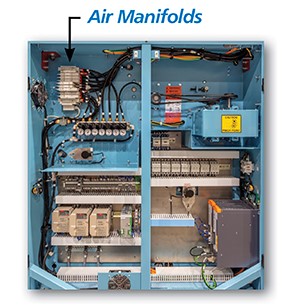

Air Manifolds

- Centrally located in the machine control cabinet.

- Each valve within the manifold provides an LED indicator which identifies if the valve is cycling properly.

Standard Features

- Automatic leading edge and width transfer programming allows for seamless transition for plants that process mixed items in a single lane

- Smooth transfer of goods from the spread mechanism to the feed tables provides an extraordinary high quality leading edge

- One transfer from operator to machine ensuring consistent part centering on each and every feed

- Pneumatic manifolds centrally located in machine for ease of maintenance and trouble shooting

- Programmable inverter conveyor drive with digital speed indicator

- Smart clamp technology with integrated photoeye for material detection – drastically reduces drops that clipless units experience!

- Small piece infeed table for feeding hand feed goods through an ironer while keeping the operators away from the infeed of the ironer.

- Working width of 120″ or 130″

- Swing down discharge conveyor to allow access to the ironer without moving the feeder

- Spread tension control via patented spread detection device ensures ideal spread of each item, even while processing mixed sizes!

Standard Features – Continued

- Casters for mobility

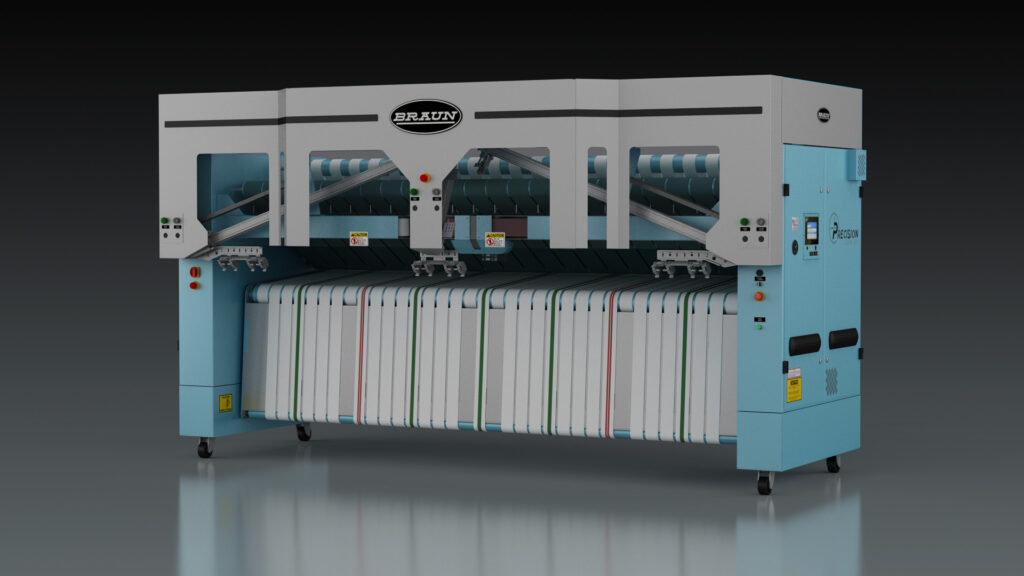

- Safety circuit guarded doors

- Illuminated emergency stops

- Illuminated feed table

- Soft start and stop to reduce wear on drive components

- Collision avoidance with jam detection

- Belt drives

- Note: Folders paired with clipless feeders are more prone to increased item reject rates (aka. folder drops) as a result of inconsistent quality of the feed/laydown process, reducing total throughput of the finishing line.

Production Counters

- Optional external production counters are available to easily monitor production by operator/station

Options

- Machine Status Lights

- ARC or automatic reject system

- Polycarbonate doors

- Machine Color

- Two or Three operator stations

- Discharge table width of 120″ or 130″

- Voltage configurations

- External production counters

- Auxilary speed encoder for automatic synchronization with non-Braun ironers

- Locking casters

- Hand feed table doffer roll

Controls

- 24 V Color Touch Screen Controls System

- Simple, intuitive, and easy to use

- Program backup to USB drive

- English & Spanish are standard (other languages are optional)

- 99 Programmable formulas for different goods

- Alarm history accessibility – very helpful while troubleshooting

- Ability to check individually activate Inputs and Outputs

Product Videos

Spreader Feeders

Feed Table and Swing Down Discharge Conveyor

Product Literature